During the process of drilling and construction of tunnels and galleries the many hazards make gas detection necessary to ensure the safety of operators and prevent potential accidents. During drilling, harmful or potentially explosive gases, such as methane or carbon dioxide, can be released and must be monitored closely.

Gas detection: methane and carbon monoxide

Methane and carbon monoxide are some of the major hazards  during drilling and construction work in a tunnel or tunnel. Methane is a colorless, odorless highly flammable gas and during excavation can be released from natural deposits in the ground or from the excavation activities themselves. If present in sufficient concentration in the air, even a small spark or heat source could cause an explosion. Prolonged exposure to high concentrations can also be harmful to human health, which is why equipping workers with portable gas detectors should be considered of paramount importance. Carbon monoxide is also an odorless and colorless gas, plus it is extremely toxic when inhaled in high concentrations. During tunnel construction, it can be emitted from vehicle and machinery engines, generators or other combustion activities. A key aspect in these environments is to have adequate ventilation, which is essential to reduce gas concentrations in the air.

during drilling and construction work in a tunnel or tunnel. Methane is a colorless, odorless highly flammable gas and during excavation can be released from natural deposits in the ground or from the excavation activities themselves. If present in sufficient concentration in the air, even a small spark or heat source could cause an explosion. Prolonged exposure to high concentrations can also be harmful to human health, which is why equipping workers with portable gas detectors should be considered of paramount importance. Carbon monoxide is also an odorless and colorless gas, plus it is extremely toxic when inhaled in high concentrations. During tunnel construction, it can be emitted from vehicle and machinery engines, generators or other combustion activities. A key aspect in these environments is to have adequate ventilation, which is essential to reduce gas concentrations in the air.

Gas detection for oxygen deficiency hazards

Another major hazard that can potentially put the lives of operators at risk is oxygen deficiency. It can be caused by various causes, such as incomplete combustion, accumulation of inert gases, or simply lack of proper ventilation. When creating a tunnel, oxygen is drawn in from outside and pumped inside to ensure proper air recycling, but it is important for operators to be equipped with portable gas detection devices for personal protection.

Our products for gas detection in tunnels and galleries

For gas detection within drilling sites, Sensitron stationary and portable gas detectors are ideal:

SMART 3G Gr.1

ATEX Group 1 certified, ideal for detecting flammable substances and toxic gases in mines, tunnels or areas classified Group 1.

CROWCON GAS PRO

Ideal for detecting up to 5 gases in a compact and robust solution. Has an easy-to-read display ideal for confined spaces.

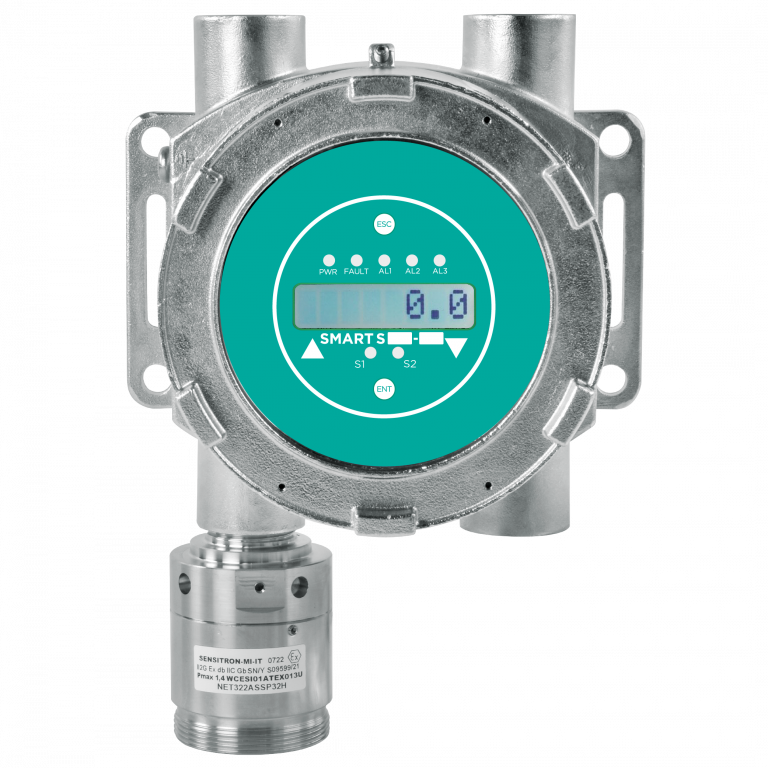

SMART S SS

ATEX certified for Zone 1, SIL2 Hardware and SIL3 Software, optional Hart Modem and with stainless steel housing.

Our certifications for tunnels and galleries

In tunnel and tunnel drilling processes, it is important that gas detection systems always ensure accurate detection, which is why certifications are a key aspect of our products:

ATEX

The Directive establishes the requirements and evaluation of equipment intended for potentially explosive atmospheres.

IECEx

The IECEx system is an international certification system. It is developed by the International Electrotechnical Commission.

SIL2 (3)

The Safety Integrity Level (SIL) is the ability to reduce the assessed risk while ensuring the reliability of the

safety systems.

Explore our spaces in virtual reality

Within the Sensitron metaverse you can explore application realities reconstructed in virtual reality. Find out more about who we are and what we do, walk inside a production area and learn more about the dangers of gas.

Follow us on Linkedin

Follow us on Instagram