The pharmaceutical industry includes the research, development, production, and commercialization of drugs and medicines. Contributing to the prevention and management of a wide range of medical conditions, this industry plays a crucial role in the global health care system. Investment in R&D of new drugs and treatments is critical to the future of the industry, as is optimization of the production and distribution departments. In addition, in order to be sold, all pharmaceutical products must meet strict safety and quality standards, whether those set by the European Medicines Agency (for the EU market) or those of the U.S. Food and Drug administration (for the U.S. market).

Gas-releted risks in Pharmaceutical Industry

Several gas-related hazards arise inside the many processes in the pharmaceutical industry, making the use of gas detection systems mandatory.

inside the many processes in the pharmaceutical industry, making the use of gas detection systems mandatory.

Risks may include:

- explosions caused by flammable substances

- high toxicity from solvents and APIs

- risks associated with oxygen deficiency

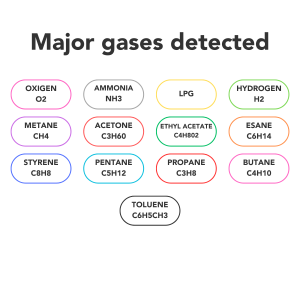

Highly sensitive sensors enable timely and accurate detection of a wide range of potentially hazardous gases, ensuring a safe working environment for employees and compliance with safety regulations. Additionally, within the production department, they allow monitoring for toxic, flammable or volatile gases that are not only a source of danger but could also compromise product quality. Even in laboratories and white rooms, gas detection helps keep the environment controlled, avoiding contamination and hazards. They are also used to monitor storage areas, detecting any gas leaks or unfavorable environmental conditions that could affect product quality or worker safety.

These applications lead to many benefits:

- increased safety in the workplace

- Early identification of potential risks

- compliance with safety regulations

Our products in Pharmaceutical Industry

Sensitron gas detection systems are suitable for use in the pharmaceutical industry, these are some of the possible solutions:

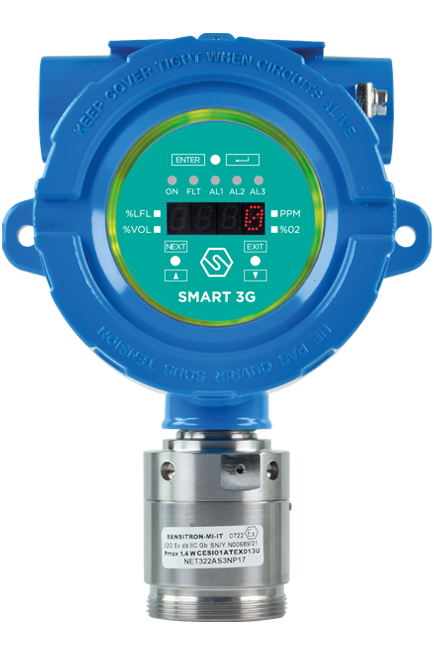

SMART 3G D2

Suitable for detecting flammable substances, toxic gases, refrigerants and oxygen in classified areas.

Certified ATEX, IECEx and SIL2/3

SMART 3G D3

Suitable for detecting in classified areas, Certified ATEX, IECEx and SIL2/3, allows non-intrusive field calibration.

MULTISCAN ++S1/++S2

Designed to meet the widest demand from the market, they allow management of up to 264 detectors. ATEX and SIL certified.

Our certifications in Pharmaceutical Industry

Due to the high risks and hazards in the pharmaceutical industry, strict safety standards must be met, which is why all our products are certified and in line with industry regulations.

ATEX

The Directive establishes the requirements and evaluation of equipment intended for potentially explosive atmospheres.

IECEx

The IECEx system is an international certification system. It is developed by the International Electrotechnical Commission.

SIL2 (3)

The Safety Integrity Level (SIL) is the ability to reduce the assessed risk while ensuring the reliability of the

safety systems.

Explore in virtual reality a Pharmaceutical Industry environment

Inside the Sensitron metaverse, you can explore a reconstructed pharmaceutical environment in virtual reality. In particular you can walk inside a production area and learn more details about gas hazards.

https://youtu.be/IjdkuaN6iBU?si=T0MpYQenR-9Cop4v

Follow us on Linkedin

Follow us on Instagram