WE DON’T COMPROMISE

+SENSE

PRECISION

WITHOUT COMPROMISES:

THE GAS DETECTOR WITH

WIRELESS INTERFACE

FACED TO THE FUTURE.

MANAGE SMART 3

BLIZARD WITH SENSE.

GAS DETECTION

WORLDWIDE.

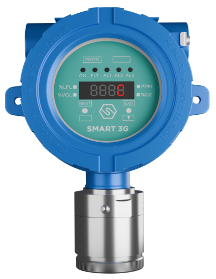

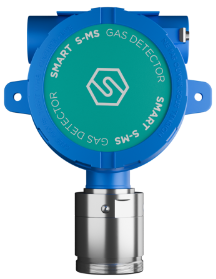

SERIES

OUR

CATALOGUE

PRODUCTS.

The product range consists of

by fixed gas detection systems

consisting of detectors and control panels

control units, for all applications.

CONTROL PANELS

Control panels are control units designed

to work in small and large systems, in all application spectrums, classified and non-classified.

SMART

S

PK

SYSTEM

CUSTOM SOLUTIONS

FOR ALL APPLICATIONS

CONTROL PANEL AND

GAS DETECTORS

CERTIFIED.

All products in Sensitron’s catalog have been tested and received certifications internationally. Risk reduction, performance evaluation, information sending and receiving systems, health requirements, performance evaluation, commercialization, and environmental care.

The Safety Integrity Level (SIL) is the ability to reduce the risk acceptable.This is achieved with safety instrumented systems (SIS), as they are designed to detect the situation of danger and take action to prevent or mitigate it.

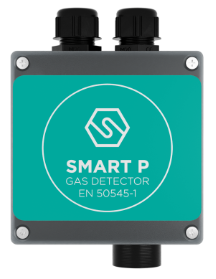

EN 50545-1 is dedicated to systems that enable the detection of toxic and combustible gases in garages. It describes the requirements for gas detectors and control units, the performance they must guarantee, and how to perform tests for evaluation.

The IECEx system is a system It was developed by the global International Electrotechnical Commission of equipment used in explosive atmospheres.

>>>

AMMONIA

FLAMMABLE

ALSO DETECTABLE BY TOXICITY

>>>

LPG

FLAMMABLE

>>>

HYDROGEN

FLAMMABLE

ALSO DETECTABLE BY TOXICITY

>>>

METHANE

FLAMMABLE

>>>

ACETONE

FLAMMABLE

>>>

CARBON DIOXIDE

TOXYC

POISONING

>>>

VOC

TOXYC

POISONING

>>>

R32

REFRIGERANT

OR TOXICITY

>>>

R152a

REFRIGERANT

OR TOXICITY

>>>

CARBON MONOXIDE

TOXYC

POISONING

>>>

OXYGEN

FLAMMABLE

AND/OR EXPLOSION

>>>

CHLORINE

TOXYC

POISONING

>>>

OZONE

TOXYC

POISONING

>>>

PROPANE

FLAMMABLE

AND/OR EXPLOSION

>>>

TOLUENE

FLAMMABLE

ALSO DETECTABLE AS VOC

>>>

BUTANE

FLAMMABLE

>>>

NITROGEN DIOXIDE

TOXYC

POISONING